|

Here is your most recent issue of the High Current News e-newsletter. It's packed full of information to keep you updated with the latest MIG & TIG welding news, product information and new updates from D/F MACHINE SPECIALTIES.

D/F is a world leader in the design, development, and manufacture of MIG & TIG welding products, consumables & accessories.

|

| Hardfacing & Overlay Torches

For automatic and robotic hardfacing applications, D/F recommends the MIG Water-Cooled-to-the-Tip Machine Barrels. These versitile torches will handle any hardfacing application. View these torches on the web site:

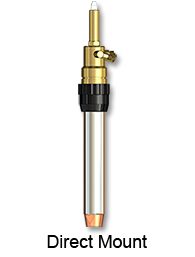

D/F Direct Mount (Automatic) Water-Cooled-to-the-Tip MIG Machine Barrels

D/F Remote Mount (Robotic) Water-Cooled-to-the-Tip MIG Machine Barrels

What is Hardfacing?

Hardfacing involves the process of layering on a tougher, stronger metal across the face of a base metal for the purpose of reconditioning a surface that undergoes much normal wear and tear demanded by the job that it is used within. Examples of these base metals might include the faces of shovel buckets, crusher plates and teeth, pipes, and extruder screws. Hardfacing is often applied to new products at the time of production to increase the life of the face from the beginning.

What Types of Demands will Hardfacing Satisfy?

Hardfacing can be used to protect agains any number of physical demands such as metal to metal wear, thermal loads, fricional and grinding wear, impact, corrosion, scaling, and many others. In some cases, more than one of these types of demands may occur simultaneously, so the weld metal must posses the respective properties. Hence, a conscientious selection of the proper weld metal will be a must. Of course, there doesn't exist a weld metal possessing all these properties in full measure. Nevertheless, in most cases it will be possible to find a satisfactory compromise in practice.

What is the Overall Benefit of Employing Hardfacing?

The initial cost and time needed to apply hardfacing to a pipe, tool, or other machine part is small compared to the time and money saved in the long run. Hardfacing will help prevent the general wear and tear associated with the work done by these tools and machines, making them last much longer, and allowing them to do much more work. Time and money are saved as the need for replacement parts and tools is kept to a minimum.

For semi-automatic hardfacing and overlay applications, D/F recommends the MIG Water-Cooled Semi-Automatic 55° Torches with External Casing. These versitile torches will handle any hardfacing application. View these torches on the web site:

D/F Water-Cooled Semi-Automatic 55° Torches with External Casing

Similar to the automatic and robotic heavy duty torches above, these semi-automatic 55 degree water-cooled torches with external casings use an axial alignment of the casing to reduce wire feed pressure and improve current tip life. The gun assembly is available with an extended handle (8"-20") and slide switch to help keep the welder away from the extreme conditions of preheat and high amperages required for overlay applications, steel casting repairs, surfacing and rebuilding applications. Because of the robust design and great success when using this torch, it can be converted form semi-automatic to automatic by easily removing the trigger switch and cable, installing a manipulator, mounting the torch on a boom, and allowing the welder to get 15' back away from the heat, thus using the trigger back by the wire feeder.

The D/F torch is famous for the fact that if it is chilled properly, the welder can grab the front of the torch with their bare hand and it will be cold to the touch seconds after welding. With the proper chiller, this can be done even after a 4 hour arc time. Make certain the cooling water supply is at least the minimum flow rate of 3 quarts per minute (for each inner body), at 40 psi (80 psi maximum) with a 5 gallon reservoir and 15,000 BTU/hr cooling capacity. D/F Machine Specialties does not manufacture or sell chillers, we only recommend them. Click here to see our recommended chillers.

If you have any questions about hardfacing, please do not hesitate to contact the factory.

Phone: (507) 625-6200 · Email: sales@dfmachinespecialties.com Phone: (507) 625-6200 · Email: sales@dfmachinespecialties.com

We look forward to helping you with your welding applications!

|

Do You Have Videos or Photos of D/F Torches in Action?

Submit Them to WIN!

D/F's new Video and Photo Galleries showcase D/F equipment in action over the years, and we are constantly adding to the galleries. We want to see how our equipment helps brings out the best of your creativity and skill, or simply how your equipment is setup and used.

Submit your videos and photos to:

HighCurrentNews@DFMachine.com

For project submissions, things to include:

- Video or Photos of your project

- What did you make?

- How did you make it?

- Which D/F products did you use?

Submissions will be put in a drawing for a chance to Win A Gift Card to your local Best Buy Consumer Electronics Store.

Check out the D/F Photo Gallery here.

Check out the D/F Video Gallery here.

|