|

Here is your most recent issue of the High Current News e-newsletter. It's packed full of information to keep you updated with the latest MIG & TIG welding news, product information and new updates from D/F MACHINE SPECIALTIES.

D/F is a world leader in the design, development, and manufacture of MIG & TIG welding products, consumables & accessories.

|

|

|

November 9-12, 2015 | McCormick Place | Chicago, IL | Booth N20066

D/F Machine Specialties would like to take this opportunity to extend our sincere appreciation to our customers for their friendship, good will and loyalty over the years. We would like to offer COMPLIMENTARY ADMISSION TICKETS to the FABTECH 2015 Welding Show at the McCormick Center in Chicago, IL, November 9-12. D/F will showcase several new heavy-duty automated and robotic MIG & TIG welding products at the show. Join us and many others as we explore most relevant and important information on industry standards, new products and latest technologies to the welding industry. Look for D/F in booth N20066. D/F Machine Specialties would like to take this opportunity to extend our sincere appreciation to our customers for their friendship, good will and loyalty over the years. We would like to offer COMPLIMENTARY ADMISSION TICKETS to the FABTECH 2015 Welding Show at the McCormick Center in Chicago, IL, November 9-12. D/F will showcase several new heavy-duty automated and robotic MIG & TIG welding products at the show. Join us and many others as we explore most relevant and important information on industry standards, new products and latest technologies to the welding industry. Look for D/F in booth N20066.

If you would like complimentary admission to FABTECH 2015, all you have to do is click here to print a copy of the tickets, or send us an email to sales@dfmachinespecialties.com with your name and desired ticket quantity. If you need assistance, please call us at (507) 625-6200. Hurry, limited ticket quantities are available. See you at the show!

FREE Product Catalog

If you cannot attend the show, we would be happy to send you a free copy of our new product catalog featuring our new and most popular MIG & TIG welding products, accessories, and consumables. Please sign up here, or send an email to sales@dfmachinespecialties.com with your name, mailing address, and desired quantity, or call (507) 625-6200. You can also download a digital copy here.

|

|

NEW D/F Product Catalog

D/F has released a brand new color product catalog! Featuring the most popular D/F MIG & TIG welding equipment, accessories and consumables, the catalog will cater to your informational and ordering needs. D/F has released a brand new color product catalog! Featuring the most popular D/F MIG & TIG welding equipment, accessories and consumables, the catalog will cater to your informational and ordering needs.

You can request your own free copy of the catalog in two ways:

1. Email D/F at sales@dfmachinespecialties.com with your name, and your company's name and address of where you would like the catalog to be sent.

2. Fill out the reservation form located here.

Click to download the catalog in digital form as a PDF. Click to download the catalog in digital form as a PDF.

|

|

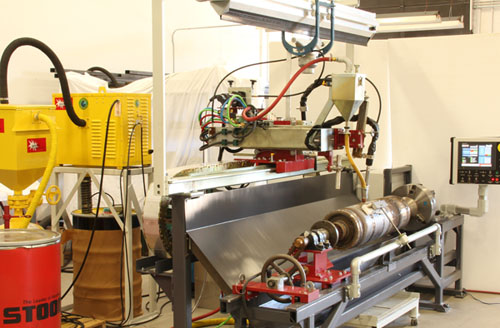

New Multi-Process Welding Lathe

from Mavrix Welding Automation, Inc.

The new PLC-based multi-process welding lathe from Mavrix Welding Automation simplifies and optimizes hardfacing and build-up welding applications. With the use of a D/F Machine Specialties high amperage, water-cooled torch, customers are now able to run sub-arc, MIG, and gasless applications in one cell.

Mavrix has launched a new line horizontal and vertical welding lathes featuring PLC-based controls. The straightforward terminology of the PLC significantly reduces the learning curve, so operators are ready to weld in minutes. With adaptive spindle speed compensation, operators do not need to adjust wire-feed speed or spindle speed to accommodate any change in diameter. Further, dual-axis step allows for any combination of surface angle.

The Mavrix multi-process horizontal lathe is capable of sub arc, open arc and gas-shielded welding processes using a single torch. An onboard second torch is ready for quick changeover for ID bore welding down to 4-inch ID. Target customers include those who remanufacture slab caster rolls, shell rolls, zinc pot rolls and mandrel bars, as well as other roll options.

Flexible, Expandable, Reliable

The highly flexible system permits the operator to develop programs by simply defining which axis will step or run when welding begins. Complementing the PLC is a 12-inch color HMI (human machine interface) and easy-to-use open-naming convention for part configuration storage. The highly flexible system permits the operator to develop programs by simply defining which axis will step or run when welding begins. Complementing the PLC is a 12-inch color HMI (human machine interface) and easy-to-use open-naming convention for part configuration storage.

The Mavrix multi-process welding lathe is preconfigured for a wide variety of accessories: servo oscillator, water cooler with loss of flow sensing, pressurized flux delivery and recover and exhaust system integration. The onboard gravity flow flux hopper includes an ultra-sonic level sensor to help reduce air consumption, inform the operator when the system is low on flux and reduce the chance of flux jams within the delivery hose. Mavrix custom builds most lathe products to fit a customer’s specific product mix.

The Mavrix lathe features the D/F Machine Specialties Water-Cooled-to-the-Tip Machine Barrel. These barrels come in a direct mount version where the torch can be mounted directly to the machine or wire feeder with the utilities coming out the back at 90 degrees to the torch, and in a remote mount version where the torch can be remounted remotely with a mounting arm, with the utilities coming straight out the top of the torch and a conduit to carry the wire from the wire feeder to the torch. Both versions come in 5" and 8" front water-cooled nozzle lengths. Each length is available with our standard size nozzles (1.125" dia.) and our high capacity Series A nozzles (1.445" dia.) for more gas coverage. The standard and Series A nozzles are interchangeable when using the correct inner parts for each.

Click here to read more about the D/F Water-Cooled-to-the-Tip Torches.

If you have any questions, please do not hesitate to contact the factory.

Phone: (507) 625-6200 · Email: sales@dfmachinespecialties.com Phone: (507) 625-6200 · Email: sales@dfmachinespecialties.com

We look forward to helping you with your welding applications!

|

|

Frequently Asked Questions

D/F has now added a Frequently Asked Questions page to the website! This page will be continually updated with information about Torch Maintenance, Welding Practice & Setup, Warranty & Refurbish, Troubleshooting, and more in hopes of fulfilling the needs of anyone who might have a common question about D/F's equipment or welding in general. Please visit the FAQ page.

|

|

Do You Have Videos or Photos of D/F Torches in Action?

Submit Them to WIN!

D/F's new Video and Photo Galleries showcase D/F equipment in action over the years, and we are constantly adding to the galleries. We want to see how our equipment helps brings out the best of your creativity and skill, or simply how your equipment is setup and used.

Submit your videos and photos to:

HighCurrentNews@DFMachine.com

For project submissions, things to include:

- Video or Photos of your project

- What did you make?

- How did you make it?

- Which D/F products did you use?

Submissions will be put in a drawing for a chance to Win A Gift Card to your local Best Buy Consumer Electronics Store.

Check out the D/F Photo Gallery here.

Check out the D/F Video Gallery here.

|

|

Words from the Editor

Greetings from D/F!

Thank you for reading our High Current News e-newsletter. Please share this issue with a friend and send us your comments.

Enjoy!

Best Regards,

Dave Judd, Editor

D/F Machine Specialties, Inc.

|

|

|

|

|

|

Follow D/F

|

In This Issue

• NEW D/F Product Catalog

• Push Torches vs. Push-Pull

• Frequently Asked Questions

• Got Projects? Submit to WIN!

• New Products

• Nozzle Thread Chaser Taps

|

New Products - Automatic Curved Machine Torches

The versatile D/F curved quick-change Water-Cooled Automatic 500 amp Torch Models NCC/LRN and HTC/LRN can be used for a wide range of automatic applications. With the various angles (22° through 90°) and lengths available, a selection may be made to suit individual requirements.

Read More

|

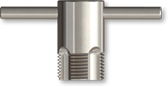

Nozzle Thread Chaser Taps

The New D/F Nozzle Thread Chaser Taps are designed to chase and tap nozzle threads to clean and repair them for better conductivity and contact.

• No need to remove the

contact tip

• Chasing will clear debris,

metal filings and spatter

• Re-tapping will straighten and

clean damaged threads

• Tap sizes available for all D/F

Nozzle Assemblies

Read More

|

Your Downloads

Did you know you can download all of D/F's Catalogs, Instruction Manuals and CAD Files at D/F's Online Download Center?

|

Contact D/F

Product Info: 1-507-625-6200

Fax: 1-507-625-6203

Online: Contact D/F

D/F Machine Specialties, Inc.

1750 Howard Drive

North Mankato, MN 56003

|

|

|

|

|

|

|

|

|