| MIG Hardbanding Torches from D/F

D/F Machine Specialties is a global leader in the design and manufacture of heavy duty automatic MIG welding torches for hardbanding service providers. These torches provide wear resistant, casing-friendly, field serviceable hardbanding. Our heavy duty torches raise the bar for tool joint wear protection.

D/F Machine Specialties has developed the Water-Cooled-to-the-Tip Automatic Remote Mount and Direct Mount Machine Barrels to provide hardbanding solutions for end-users engaged in oil and natural gas exploration, transportation and processing applications in the U.S., Canada, and throughout the world. These 850 amp, 100% duty cycle torches improve weld quality, reduce downtime, extend consumable life, and allow greater productivity when hardfacing and hardbanding.

- Increases Contact Tip Life up to 7-to-1

- Torch body lengths, sizes, and profiles available for any application

- Water-Cooling on the Contact Tip

- Water-Cooled Nozzle Assembly

- Torch Longevity - Years vs. Months

- 100% Duty Cycle up to 1000° Preheat, 850 Amps

- Easy Connection to All OEM Machines

- Slip-In Or Threaded Contact Tip Models Available

- .035”-1/8” Hard/Cored, 3/64”-1/8” Aluminum

- Direct Replacement To Linde/Esab ST-12

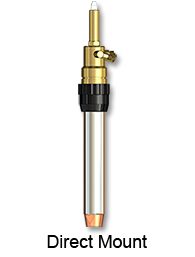

Besides how well built our torch is, it is also popular in the hardbanding industry because it is available in 2 different profiles (automatic/direct mount and remote mount). A majority of the welders performing hardbanding prefer the automatic (direct mount, pictured above) version because they are either plugging the torch directly into the wire feeder or they are using the direct mount torch as a remote mount torch with an adapter on top that accepts the casing/conduit to bring in the wire. This gives them a profile that is very easy to work on when they need to change a liner, conduit, or power cable. The D/F torch attaches to what we call a Utility Station, as it is not a unitized torch (we have separate utilities for the gas, water and power). The Utility Station will last forever, and it makes for a very safe, neat, and clean installation. Further, the Utility Station enables the torch to operate at high amperages and for long duty cycles because it allows for more power handling and water-cooling than the competition’s torches.

These Water-Cooled-to-the-tip torches have a 650 amp continuous duty cycle power cable that has been tested and run by Fanuc and Lincoln Electric for 250,000 robotic cycles at 650 amps. If you have a job that requires more than a 650 amp cycle, the torch can be retrofit with two of the 650 amp power cables which in theory will allow 1300 amps to be put on the torch. Customers are running these torches at 850 amps on continuous duty cycles above 1000 degree pre-heat, 3 shifts per day all year round. That alone is a testament to how robust in design these torches are.

The Model NCM torch accommodates slip-in contact tips held by a collet nut. The Model HTM torch accommodates threaded contact tips. Combined the models will run .035"- 1/8" hard wire, cored wire, and aluminum wire.

D/F welding guns are designed to last for years instead of months. If needed, D/F torches are completely repairable and very easy to maintain. Our consumables are always in stock and are 1/3 of the cost of competitors'. Customers have been perpetually pleased to find out that we ship every order within 3 days of receipt of a purchase order, and that we are always willing to ship our equipment for next-day delivery if needed.

Hardbanding Solutions Europe

“The first dedicated hardbanding equipment manufacturer in Europe has arrived, and they chose the D/F torch.

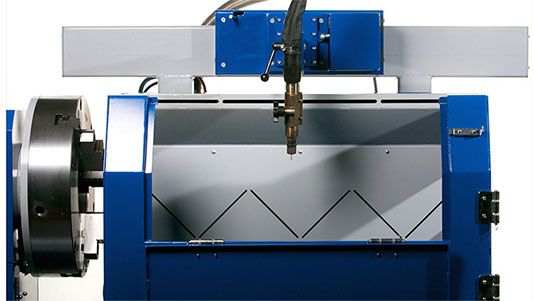

Hardbanding Solutions Europe is a young company based in rural South West Scotland. Incorporated almost 5 years ago, they established themselves as a ‘Technical Centre’ for US hardbanding wires such as Duraband NC, manufactured by Postle Industries in Cleveland, Ohio.

Last year the company decided to expand its operations, and the logical choice was to design and build specialized hardbanding equipment. With more than three decades of experience in hardbanding between the three directors of the company, they knew that the welding equipment had to be built to withstand some rough treatment. Hardbanding involves the protection of drill pipe tool joints and casing from wear using a hardfacing process, for oil and gas drilling operations. These machines must be capable of running all day and night, in both factory and field conditions.

The units are made entirely of parts from the USA and the EU. The choice of welding torch was vital to reliability, as it’s often the torch that will come under the most strain. Darren Mathieson, the company’s technical director, commented, ‘We needed a torch which was robust, and extremely reliable. A torch that would continue to work at full capacity after taking a few, inevitable knocks. The arc energy and heat involved in hardbanding is high and our well-organized customers have the welding unit working almost constantly. So we chose the DF machine style barrel, water-cooled to the tip. We have not been disappointed; they perform very well for this application.’

You can see the full range of hardbanding equipment, and find out a little more about the company, at their new website: www.hardbandingequipment.com.”

- Hardbanding Solutions Press Release, July 2016

Click here to read more about the D/F Automatic (Direct Mount) Water-Cooled-to-the-Tip Machine Torches.

Click here to read more about the D/F Remote Mount Water-Cooled-to-the-Tip Machine Torches.

Due to the fact that every welding application is different because of size restrictions, access restrictions, positioning restrictions, etc., we have a solution for your unique application. By using separate utilities and a Utility Station, the D/F torches can carry more power, run cooler, provide more gas coverage, withstand extreme conditions (1000 degree pre-heat), increase weld quality (X-ray quality welds), and run the full range of wire through 1/8".

Click here to read more about D/F torch connection options.

If you have any questions about hard automation applications, D/F torch connection options, or about the D/F Fixed Automation Water-Cooled to the Tip torches, please do not hesitate to contact the factory.

Phone: (507) 625-6200 · Email: sales@dfmachinespecialties.com Phone: (507) 625-6200 · Email: sales@dfmachinespecialties.com

We look forward to helping you with your welding applications!

|